Solon 16F168718 Flange Washer, Imperial, 1 in, 1.032 in ID, 1.805 in OD, 0.17 in Thick, Inconel, Plain

SOLON® 16F168718 Flange Washer, Imperial, 1 in, 1.032 in ID, 1.805 in OD, 0.17 in Thick, Inconel, Plain

SOLON® 16F168718 Flange Washer, Imperial, 1 in, 1.032 in ID, 1.805 in OD, 0.17 in Thick, Inconel, Plain 16F168718- Brand Name: SOLON®

- PN: 16F168718

- Min. Order Qty: 1

- Qty. Interval: 1

- Click for Availability

Certain industries that utilize piping flange joint assemblies, such as petrochemical, dictate a low tolerance for fugitive emissions. Flange live loading, which is a process imperative to controlling gasket leaks in piping and refining operations, depends on the mission-critical performance. It is estimated that up to 92% of all flange leaks are caused by insufficient or loss of bolt preload. Solon brand Flange Washers are designed to maintain sufficient bolt tension and resultant gasket stresses in high temperature and high-pressure applications where safety and emission containment take priority. Solon brand Flange Washers are simply Belleville springs that are designed to be used in flange applications. The springs are engineered to fit into flange designs and the loads are typically higher than standard Belleville washers. Engineered to withstand extreme temperatures as well as corrosive environments. Contact us for an engineered solution to your custom specifications and unique application requirements. Made in USA.

| Additional Information | : | 139.45 ft-lb Unlubricated Torque, 174.31 ft-lb Lubricated Torque |

| Deflection at Working Load | : | 0.023 in |

| Finish | : | Plain |

| Flat Load | : | 11950 lb |

| Grade | : | 718 |

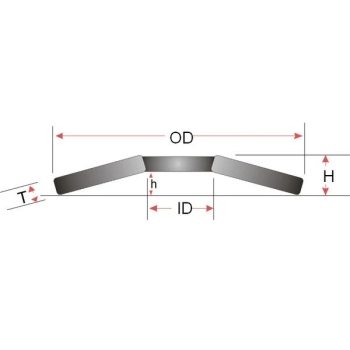

| Height | : | 0.195 in |

| Inside Diameter | : | 1.032 in |

| Material | : | Inconel |

| Nominal Size | : | 1 in |

| Outside Diameter | : | 1.805 in |

| System of Measurement | : | Imperial |

| Thickness | : | 0.17 in |

| Working Load | : | 10460 lb |

- Once installed, they don't have to be retorqued

- Eliminate the effects of differential thermal expansion

- Increase the elasticity of the bolting system by a factor of 7 to 15X

- Economical alternative to costly system enhancements

- Maintain bolt integrity by maintaining the contact pressure between the flange and gasket surfaces

- Comprehensive risk analysis - contact a SOLON® application engineer for a detailed application review

Add To Favorites List

Add To Favorites List